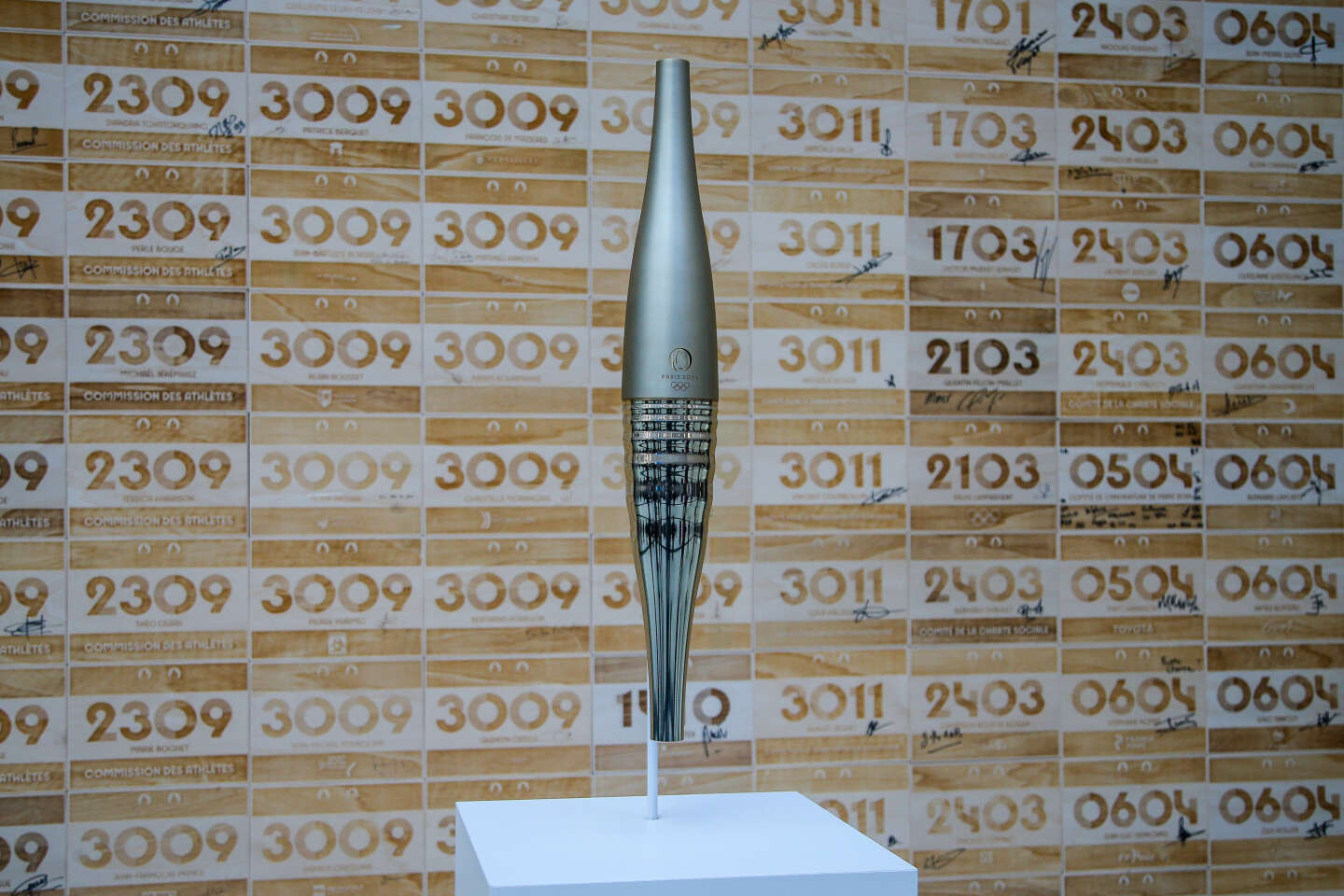

The Olympic torch, on display at the headquarters of the Organizing Committee for the Olympic and Paralympic Games, in Saint-Denis (Seine-Saint-Denis), July 26, 2023. JEE/SIPA

The ArcelorMittal site in Florange (Moselle) had not seen so many journalists since the years of François Hollande’s presidency (2012-2017). The difference is that they were not greeted, Thursday, April 4, by lines of angry unionists, but by management with all smiles. It was first in its “digital lab”, symbol of the modern shift taken by the site, that the steelmaker presented the Olympic and Paralympic flames for which it supplied the steel.

If the slab – the blocks of steel used for manufacturing – arrived from the Châteauneuf site (Loire), between Lyon and Saint-Etienne, it was in Florange that it was hot and cold rolled. The reels were then sent to the Woippy site (Moselle), where the sheets were cut before being sent to different partners who carried out the assemblies.

This long-term work resulted in this slender object 70 cm high, weighing barely 1.5 kg and with a steel thickness of just 0.7 mm. A feat, assures Franck Wasilewski, project manager: “Everything was made in France and required around 8,000 hours of development. It was necessary to transform the image sent by designer Mathieu Lehanneur into a unique object with quasi-industrial production. Everything has been a technological challenge. It forced us to step out of our comfort zone. »

Read the report: Article reserved for our subscribers In the workshop of… Mathieu Lehanneur, designer with Olympic form

Add to your selections

The Maizières-lès-Metz research center, located a few kilometers from Florange, worked there with that of Avilès, in Spain. “We had to be really innovative. We proposed different prototypes in different materials, carried out heat resistance tests”adds Jean-Luc Thirion, at the head of the Moselle center, which will be crossed on June 27 by the Olympic relay.

“We used low carbon emission steel, a symbol of the turning point taken by the steel industry. The precision and finesse of our large industrial tool were made available to this object of art”, comments Jean-François Malcuit. The factory manager is by far the proudest. He knows where his site has gone. “Florange is still there”, the leader proclaims to the general public. He refers to 2012, when François Hollande witnessed, helplessly, the closure of the blast furnaces, then dragging it like a ball and chain for the rest of his five-year term, after having seen his prime minister, Jean-Marc Ayrault, and his minister of productive recovery, Arnaud Montebourg, torn around nationalization.

“Florange is today a center of excellence”

You have 46.55% of this article left to read. The rest is reserved for subscribers.

2024-04-04 17:30:00

#manufacture #Olympic #torch #reignites #ArcelorMittal #flame #Florange

:quality(85)/cloudfront-us-east-1.images.arcpublishing.com/infobae/AZ3N42J6TVHD7GEQEP4JJDLN6M)